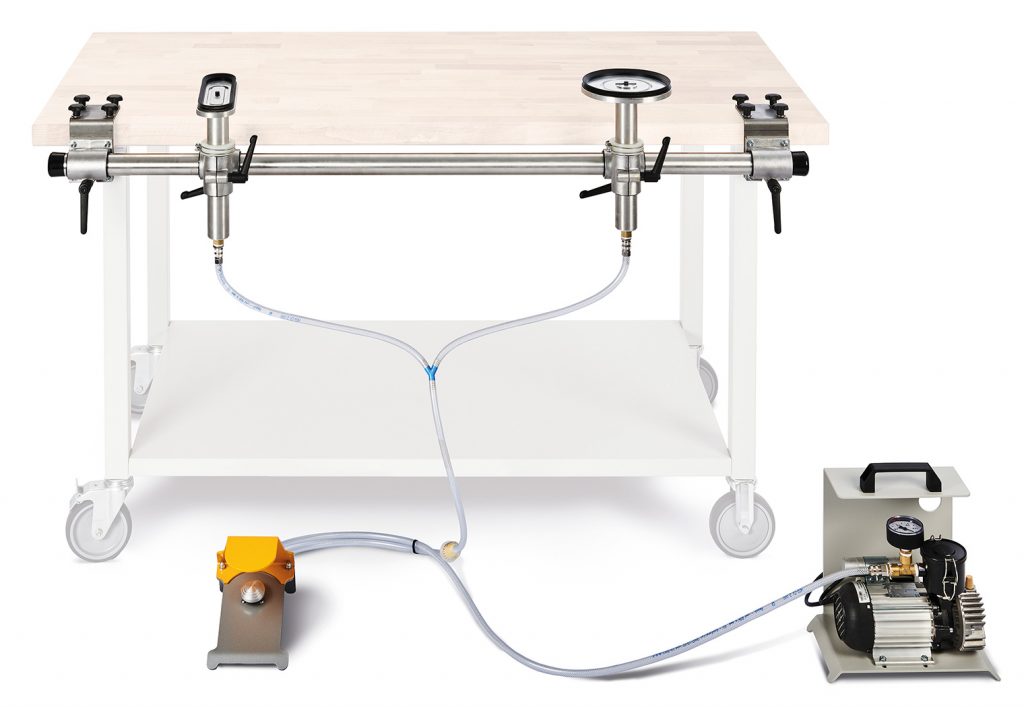

The retrofit kit is easy to attach on existing workbenches. The original vacuum clamping technology makes it particularly easy to machine a wide variety of workpieces.

bankmaster® Workbench Top

- DOSCORNIO®

- Product Overview

- bankmaster® Vacuum Clamping Systems

- bankmaster® Workbench Top

Your Advantage

- Compact and robust design

- Vacuum plate with full 360° rotation

- Efficiently work on small or large work pieces

- Flexible use in the workshop

- Ergonomic operation

- Robust, manoeuvrable and mobile

Product video

Product description

Large panels, narrow components, delicate workpieces, pipes – be they made of wood, plastic, or metal – are usually difficult and unwieldy to process.

The solution is as ingenious as it is cost-effective: endlessly rotating bankmaster® vacuum plates allow fast and damage-free machining in an ergonomically optimal position. Even workpieces, parts, and components with delicate surfaces, such as stainless steel, can be clamped quickly, safely, and without causing damage.

Rejects and rework are reduced by correct clamping. The processing time can thus be significantly reduced and manufacturing costs can be cut back immensely.

The flexible, mobile bankmaster® workbench attachment with its compact, robust design can be easily and effortlessly mounted on existing workbenches. Flexible, 360° rotatable vacuum plates ensure the ideal working position, especially for edge processing.

A powerful vacuum pump with a practical holder allows the workpieces to be fixed in place in seconds. Both hands are free for the actual machining task thanks to the simple handling and convenient release with the foot valve. This enables the economic machining of small and medium-sized workpieces.

The bankmaster® workbench attachment is manufactured from high-quality materials for professional, long-term use: The suction plates are made of aluminium and the sealing lips used are made of special plastic which is particularly resistant.

Standard Scope of Delivery

- Vacuum pump 3 m³/h

- Foot valve with tubing

- Vacuum plate round Ø 160 mm and oval 220 x 70 mm (L x W), both with full rotation

Technical Data

- Dimensions Workbench Top: 1,410 x 290 x 310 mm (L x W x H)

- Device weight without vacuum pump: approx. 6.7 kg

- Device weight foot valve with tubing: ca. 1.7 kg

- Device weight vacuum pump incl. support: approx. 8.3 kg

- Performance vacuum pump: 3 m³/h

- Vacuum pump rated voltage: 220-240 V, 50/60 Hz

Options

- Other variants of vacuum plates (find more details here)

- tubestar® adapter plate for tubes

You have any questions about our products?

We are happy to provide more information.

Phone: +49 (0)7681 - 24100

or Mail: info@doscornio.com